Why stainless steel is "stainless"?

Stainless steel is corrosion resistant because of the addition of chromium which prevents rust in steel. Chromium works as a barrier to prevent iron oxidation from contacting with air. In general, stainless steels contain at least 10.5% chromium despite of varied grades. The addition of other elements such as nickel, titanium, copper, niobium, aluminum plus the varying content of chromium is to enhance the steel mechanical and physical properties.

When and How stainless steel is discovered?

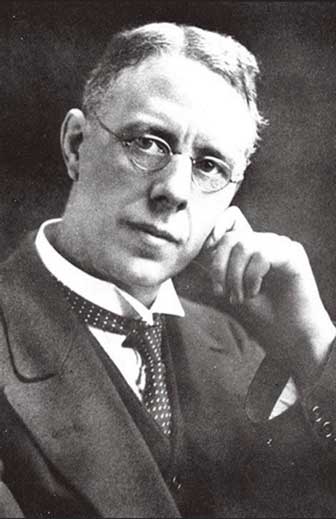

The origin of chromium steel can be traced back to the manufacture of steel and chromium alloy weapons in the 11th century at Chahak in ancient Persia (modern Iran), but it is until the 19 century that stainless steel is widely known through the chance discovery of Harry Brealey. As a research director of Brown Firth Research Laboratories at Sheffield, Brealey was in charge of finding the right material for rifle barrels to resist erosion caused by gunfire heat. He selected chromium to add into the steel composed of iron and carbon due to the high melting point of chromium. Though the solution for erosion by the heat of gunfire remained unresolved, he accidentally found the mix of chromium into the steel can prevent rust, despite the chromium steel being exposed to air and water for years.

It might be not fair to credit this technological breakthrough to Brearley alone as he found a patent already existed in the name of Elwood Haynes (the two men joined forces to create the American Stainless Steel Corporation). However, we all owe a lot to Brealey who extended the use of stainless steel to civil use. Before him, the chromium steel is restrained in the scope of weaponry and some structures.

When Brealey found this chromium added steel was also corrosion resistant to acidic foods such as vinegar and lemon, with Sheffield being the cutlery manufacturing center in England, the application became natural. Though at the time cutleries free from rust were mainly made by silver and used by the wealthy, years of improvements in quality and mass production make possible stainless steel the metal choice for kitchenware and other fields. It is in 1930 when stainless steel was firstly used in a skyscraper, i.e., the Chrysler Building in New York.

The Commercialization of Stainless Steel

Hundreds of different stainless steel grades have been developed according to the addition of chromium and other alloying elements as mentioned above, but overall stainless steels can be classified into 5 categories: 1) austenitic stainless steel (typical 304), 2) ferritic stainless steel (typical 430), 3) martensitic stainless steel (typical 420), 4) precipitation hardening stainless steel (typical 630/17-4PH) and 5) duplex stainless steel (typical S31803/2205).

- - Among all commercialized stainless steels, austenitic stainless steel accounts for 70%, while 304 as its most common grade accounts for more than 50% of stainless steel consumption.

- - Ferritic stainless steels, due to lack of rare elements stay as plain chromium steels. 409 is the cheapest stainless steel grade for containing only up to 10.5% chromium, but it is good material for auto exhausts for the combined factors of low price, easy formability and corrosion resistance.

- - Martensitic grade 420 stainless steel is widely used in engineering applications, such as 420 stainless steel seamless pipes for diesel engines. Martensitic 440C stainless steel remains the hardest and the most wear resistant stainless steel of all and common use is the cutter.

- - 630/17-4PH is the most common precipitation hardening stainless steel, are widely used in bicycle components and surgical knives for its very high strength, good weldability and corrosion resistance.

- - Duplex stainless steel, for embodying the advantages of high corrosion resistance of austenitic stainless steel and high strength of ferritic stainless steel at the same time, it is duplex as it called. It means, it can save material in comparison with austenitic stainless steel for the same working load and pressure. For the combined advantages, 2205 duplex stainless teel are mostly seen in chemical tanks, refineries and some heat exchangers.

Contact CIVMATS for Stainless Steel Purchasing

At CIVMATS, we manufacture stainless steel materials according to your specific demand. Shapes, grades, finish, dimension, and mechanical properties are customizable. We are very excelled at customization of stainless steels. If you have very demand for niche market applications, we are exactly what you are looking for. Welcome to consult with us for FREE.

- Email: sales@civmats.com

- Phone: 86-519 8180 9659