Overview

Stainless steel tube is nothing uncommon in Feedwater Heater Tube (FHT) use, whether in the fields of nuclear energy or boilers. Even in boiler market alone, there are industrial boilers and utility boilers differentiated in size, design & applications. As introduced in previous article, stainless steels are available in various grades to meet varied FHT applications. This article will mainly focus on the difference between stainless steel welded tube and seamless tube for your better decision making process.

Specifications

Below listed are the two most popular specifications for the production of stainless steel seamless and welded tubes respectively for FHT purpose:

- 1) ASTM A213/213M: Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, Heat-Exchanger Tubes

- 2) ASTM A249/A249M: Standard Specification for Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger and Condenser Tubes

Economic Factor

The processes involved for the production of stainless steel seamless tubes are more complicated than those for stainless steel welded tubes, hence it is always more expensive for the same dimension. Since stainless steel seamless tubes are produced from round bars punching with no welding seams, it is regarded better than stainless steel welded tube in corrosion resistance and bearing pressure. After all, welding seam, if not dealt well, can constitute a weak point in the whole FHT system. However, this doesn’t mean welded tube is inferior in quality than seamless stainless steel tubes.

Actually, stainless steel welded tube also has its advantages such as lower production cost (therefore lower price), better finish and more uniform thickness. The production technology introduced by VHET for producing welded stainless steel tubes under ASTM A249/A249M is already sophisticated and widespread in FHT related fields. The qualified tubes produced according to the specification, whether in terms of seamless or welded, shall both serve for its designated applications. To skip economic factor, we need to learn a lot more of stainless steel welded tubes for EFH purpose.

Advantages & Disadvantages of Stainless Steel Seamless Tubes

Stainless steel seamless tubes are made from stainless steel bars; hence they have no welding seams (or weak point) with the above-said advantages. As a matter of fact, stainless steel tubes for FHT application are always small in diameter, typically in 15~18mm OD. Even for utility boiler uses, the OD is hardly larger than 90mm. With several rounds of drawing process, stainless steel seamless tubes can also become quite uniform in thickness.

However, as more processes are involved, the delivery time is way longer and it is more costly. For customization, it can take 2 to 3 months. Yet still, the finish can be hardly as good looking as welded tubes in many cases.

Advantages & Disadvantages of Stainless Steel Welded Tubes

Stainless steel welded tubes produced under specification ASTM A249/A249M are quite different from ss weld tubes for general purposes, mainly in that its annealing process is done online, which will also be illustrated in the advantages to be introduced as below:

1) No carbon contamination

As stainless steel welded tubes produced with VHET technology don’t necessitate lubricant for formation or reducing process, the tubes will not be exposed to carbon contamination during annealing. On the contrary, lubricant use and degreasing are inevitable processes for drawing stainless steel seamless tubes. Since tubes serving for this purpose usually are U-shaped with long length, such as 15 meters or above, the inside wall degreasing will be hardly complete.

2) Minimum Residual Stress

Stainless steel welded tubes produced with VHET technology don’t involve straightening process, as the annealing is done online with the tubes staying straight before and after. This can reduce the residual stress to the minimum. For seamless stainless steel tubes entail straightening process, which can produce marks on the finish and introduce large residual stress. The residual stress can have negative effects on stress corrosion resistance (SCC). For example, stainless steel 304 is quite vulnerable to this kind of stress corrosion when exposed to the working condition of high temperature and high pressure.

3) No risk of Chromium Depletion or Overpickling

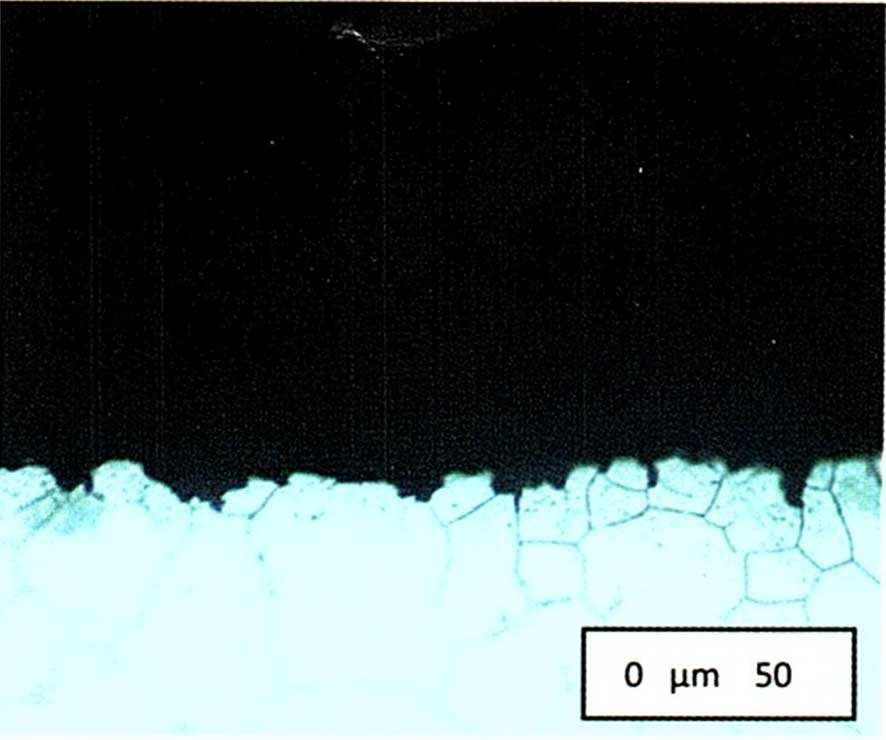

After annealing, stainless steel seamless tubes need to be pickled to remove oxide layer and chrome-depleted layer. Due to the long length and small inside diameter of the tubes, the pickling process can be difficult. If it is underdone, the chrome-depleted layer can hardly be removed totally. If it is overdone, it will lead to overpickling. (as photo below). Overpickling can give rise to rough finish and increased pipe pressure drop. While stainless steel welded tubes produced with VHET technology can avoid these potential risks for no pickling process is required. Stainless steel welded tubes produce with this technology can thus be environmental-friendly (no nitride waste is produced) and safe in use (no HF acid).

4) Strict Non-Destructive Test

According to ASTM A249, eddy current test is compulsory for producing stainless steel welded tubes for serving FHT projects. However, to avoid the risks from the defects which other NDT methods can fail, at CIVMATS CO. LIMITED we make UT test as compulsory. This should be specifically indicated in the contract for purchasing ASTM A249 stainless steel welded tubes as it is not compulsory according to specification ASTM A249. The risk brought from the undetected defects that can lead to pipeline failure, which can be especially dangerous for equipment operating under high temperature and high pressure. For this reason, we suggest both eddy current test and UT test to mitigate any potential risk. This is also introduced in our previous article titled difference among stainless steel materials. Click here and to learn more.

5) Minimize risk of transportation during production

Online annealing can avoid the risk of transporting the stainless steel welded tubes from one equipment to another equipment, which is inevitable for stainless steel seamless tubes. To avoid pits, dents, stress or deformation, careful measures should be taken during transportation for stainless steel seamless tubes. However, ASTM A249 stainless steel welded tubes can minimize the threats that come from transportation.

CONTACT CIVMATS

If you are in the market for ASTM A249 stainless steel welded tubes, we are exactly what you are looking for. CIVMATS CO. LIMITED will always be your most reliable choice.

- Email: sales@civmats.com

- Phone: 86-519 8180 9659