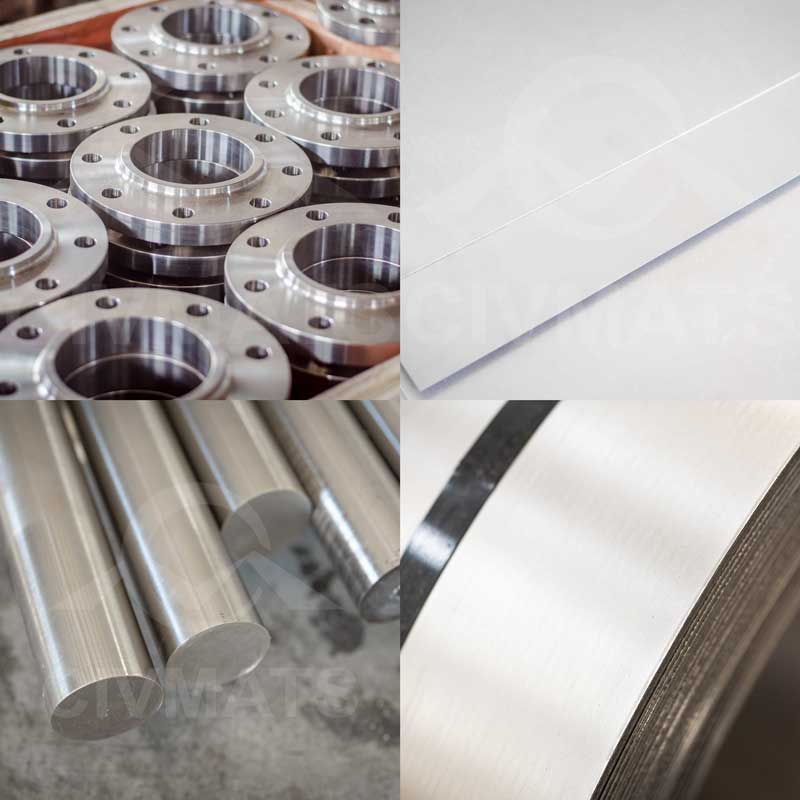

STAINLESS STEEL 17-4PH

Overview

17-4PH is a precipitation hardened(PH) martensitic stainless steel consisted of copper and niobium/tantalum. This grade features high strength, hardness and corrosion resistance. Its mechanical properties can be optimized by heat treatment with the compression strength achieving up to 1100-1300 mpa (160-190 ksi). This type can be strengthened by directly obtaining martensite structure after solution treatment. With subsequent aging treatment, the precipitation hardened phase (including copper phase) is further strengthened. Due to low carbon content, it features better workability, corrosion resistance and weldability than Martensitic Stainless Steels such as Cr13 and 9Cr18 and 1Cr17Ni2.

Features of Inox 17-4PH

17-4PH alloy features excellent corrosion resistance, superior to any other hardenable stainless steel. In most cases, it has as good corrosion resistance as type 304. Despite this, stress corrosion can happen under a high-strength state; if there is a risk of stress corrosion cracking, it will be necessary to adjust the stabilization temperature. The alloy 17-4PH is susceptible to corrosion or crack corrosion in static seawater. However, in the petrochemical, food processing and paper industries, its corrosion resistance matches grade 304L

17-4PH embodies the advantages of austenitic steel after solution treatment and is easy to work with. It can obtain high strength through intermediate pressure treatment and aging treatment, so it is widely used in pressure vessels, aircraft and steam turbine blades. It is mainly used for these parts because they are either in contact with the medium or highly stressed. For example, if the impeller is in direct contact with the medium, it poses high requirements on the corrosion resistance of the material used. Since the shaft must drive the rotor components such as the impeller to rotate together, it is subject to large force, requiring very good strength and toughness to operate. The mechanical properties required for its materials, hence, must be very good. That’s how 17-4PH comes into play as its corrosion resistance and mechanical properties meet these two requirements.

17-4PH Applications

- 1) Offshore platforms, helicopter decks, other platforms;

- 2) Food industry;

- 3) Pulp and paper industry;

- 4) Aerospace (turbine blades);

- 5) Mechanical components;

- 6) Nuclear waste barrel;

- 7) Surgical instruments;

- 8) Others.

Tags

Grade 17-4PH, Type 17-4PH, Inox 17-4PH, AISI 17-4PH, AISI 630, SUS 630, 1.4542, UNS S17400, Acero 17-4PH.

Contact

If you want to buy 17-4PH stainless steel products, please contact the RIGHT supplier - CIVMATS to get the latest price.

Chemical Composition

Data Sheet

| ASTM / AISI | DIN | JIS | GB |

|---|---|---|---|

| 17-4PH, 630 | 1.4542 | SUS630 | 05Cr17Ni4Cu4Nb |

| σb (Mpa) | σs (Mpa) | δ% | HB | HRB | HV |

|---|---|---|---|---|---|

| ≥ | ≥ | ≥ | ≤ | ≤ | ≤ |

| 1310 | 1170 | 5 | 477 | 48 | / |