STAINLESS STEEL 430

Overview & Features

Type 430 is a commonly used stainless steel with good corrosion resistance. It features better thermal conductivity than Austenite with smaller thermal expansion coefficient. In addition, it embodies good heat fatigue resistance and stress corrosion resistance. It is a typical non-heat treated hardenable ferritic stainless steel. Since titanium is added as the stabilizing element, the welds of the steel has good mechanical properties. Also, it is becoming a replacement for 304 stainless steel in many applications for its lower price.

Grade 430 has good corrosion resistance in oxidizing acid solutions, especially in nitric acid, it is therefore widely used in the manufacture of chemical equipment for the production of nitric acid, such as absorption towers, nitric acid heat exchangers, acid tanks, transfer pipes and tanks. Because it is safety and non-toxic, it is widely used in the production of food, wine and other industrial pipes and tableware.

Finish of Inox 430

430 stainless steel has varied finishes. Different finishes means distinct performance of dirt resistance and corrosion resistance.

- 1) 1D – The finish has discontinuous granules, also known as matte finish. Processing technology: hot rolling + annealing shot pickling + cold rolling + annealing pickling.

- 2) 2D – The finish shows a slightly shiny silvery white. Processing technology: hot rolling + annealing shot pickling + cold rolling + annealing pickling.

- 3) 2B – The finish shows silver white with better gloss and flatness than 2D finish. Processing technology: hot rolling + annealing shot pickling + cold rolling + annealing pickling + quenching and temper rolling.

- 4) BA – The finish gloss is excellent with a high reflectivity, like the mirror finish. Processing technology: hot rolling + annealing shot pickling + cold rolling + annealing pickling + finish polishing + temper rolling.

- 5) No.3 – The finish features good gloss with rough grain. Processing technology: polishing and temper rolling for 2D or 2B with 100~120# grinding (JIS R6002).

- 6) No.4 – The finish features good gloss and fine lines. Processing technology: polishing and temper rolling for 2D or 2B with 150~180# grinding (JIS R6002).

- 7) HL – The finish shows silver gray with hairline stripes. Processing technology: polishing 2D or 2B finish with an appropriate size of grinding material to continuously polish the finish.

- 8) MIRRO – The finish is as reflective as a mirror. Processing technology: grinding and polishing the 2D or 2B with an appropriate grinding material to a mirror finish.

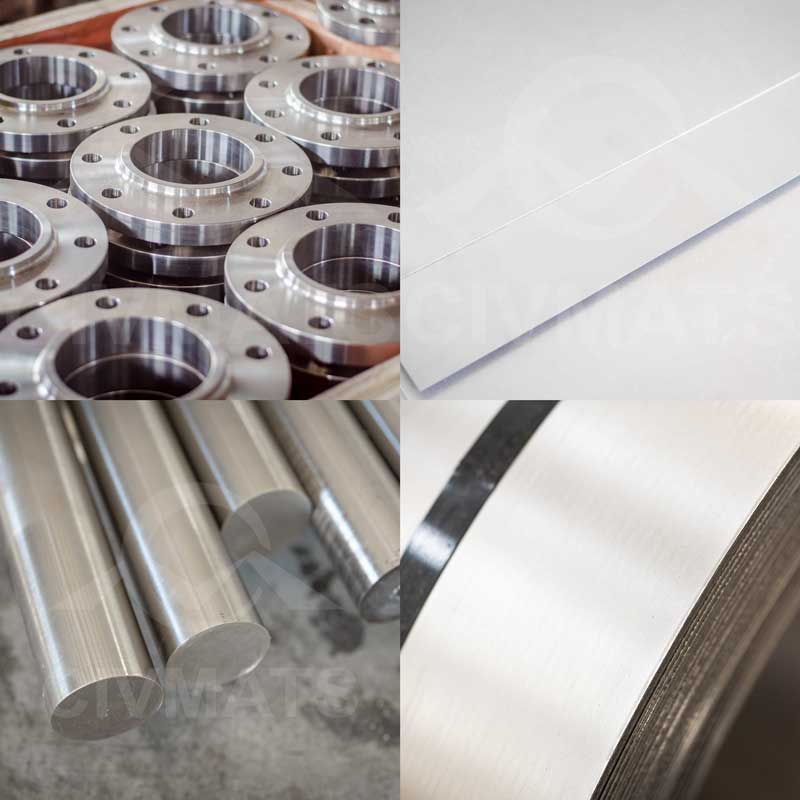

430 Applications

- 1) Building Decoration;

- 2) Heavy oil burner parts;

- 3) Household appliances;

- 4) Home appliance parts;

- 5) Outdoor advertising column;

- 6) Products with stress corrosion resistance requirements;

- 7) Electronic product;

- 8) Tableware;

- 9) Bolts, nuts, screens and burners;

- 10) Others.

Tags

Grade 430, Type 430, Inox 430, AISI 430, SUS 430, 1.4016, UNS S43000, Acero 430.

Contact

If you want to buy 430 stainless steel products, please contact the RIGHT supplier - CIVMATS to get the latest price.

Chemical Composition

Data Sheet

| ASTM / AISI | DIN | JIS | GB |

|---|---|---|---|

| 430 | 1.4016 | SUS430 | 10Cr17 |

| Heat Treatment Temperature |

σb (Mpa) | σs (Mpa) | δ% | HB | HRB | HV |

|---|---|---|---|---|---|---|

| °C | ≥ | ≥ | ≥ | ≤ | ≤ | ≤ |

| 780-850 | 450 | 205 | 22 | 183 | 89 | / |