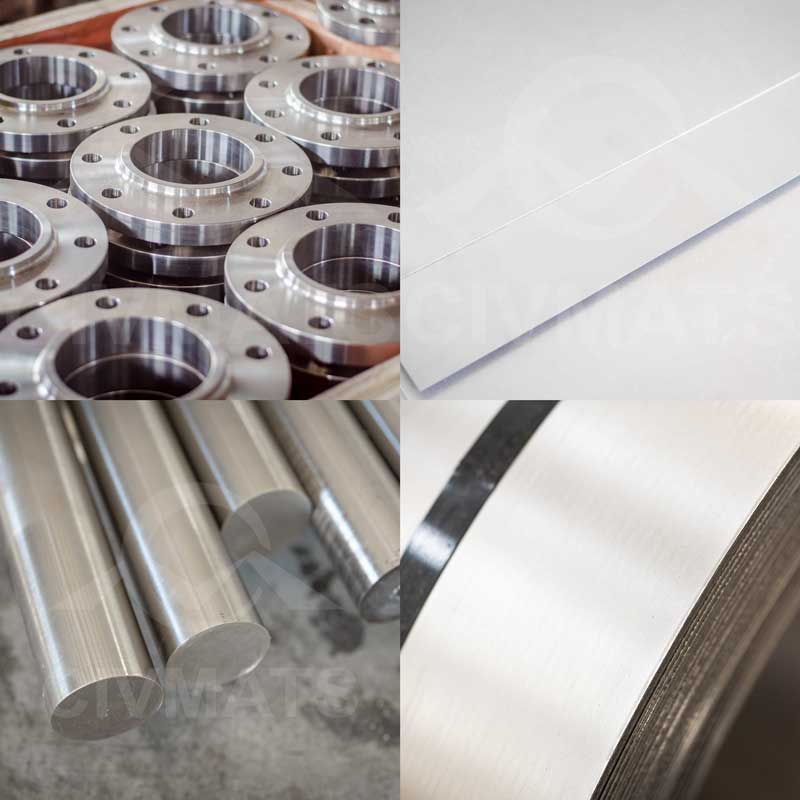

STAINLESS STEEL S32205

Overview & Features

Duplex stainless steel alloy S32205(S31803) is composed of 22% chromium, 2.5% molybdenum and 4.5% nickel-nitrogen alloy. It features high strength, good impact toughness and good overall and local resistance to stress corrosion. The yield strength of S32205(S31803) duplex stainless steel is more than double as high as that of common Austenitic stainless steel, allowing designers to reduce weight when designing products. On this ground, this alloy is more competitive than 316 and 317L. S32205 is especially suitable for use in the temperature range of -50°F / +600°F, beyond which, this alloy may also be considered to use, but with some limitations, especially when applied to welded structures.

Advantages of Inox 2205

- 1) The yield strength is more than twice as high as that of common Austenitic stainless steel, featuring sufficient plastic toughness required for molding. The thickness of the tank or pressure vessel made of duplex stainless steel is 30-50% lower than the commonly used austenite, which is beneficial to reduce cost.

- 2) It has excellent resistance to stress corrosion cracking. Even the duplex alloy with the lowest alloy content has higher resistance to stress corrosion cracking than Austenitic stainless steel, especially in the environment containing chloride ions. Stress corrosion is a prominent hazard difficult to solve in common Austenitic stainless steels.

- 3) The most common S32205(S31803) duplex stainless steel used in many media has better corrosion resistance than ordinary 316L Austenitic stainless steel, while super duplex stainless steel has higher corrosion resistance. In some media, such as acetic acid and formic acid, super duplex stainless steel can even replace high-alloy Austenitic stainless steels and even corrosion-resistant alloys.

- 4) It has good local corrosion resistance and is superior to Austenitic stainless steel in wear and corrosion resistance as well as fatigue corrosion resistance compared with Austenitic stainless steel with equivalent alloy content.

- 5) Compared with Austenitic stainless steel, it has a lower coefficient of linear expansion and is close to carbon steel. It is suitable for linking with carbon steel and thus has important engineering significance, such as producing composite plates or linings.

- 6) Compared with Austenitic stainless steel under dynamic or static load conditions, it has higher energy absorption capacity. Duplex stainless steel has obvious advantages and has practical application value when coping with unexpected accidents such as collisions and explosions.

S32205 Applications

- 1) Pressure vessels, high pressure storage tanks, high pressure pipelines, heat exchangers (chemical processing industry);

- 2) Oil and gas pipelines, heat exchanger fittings;

- 3) Sewage treatment system;

- 4) Pulp and paper industry classifiers, bleaching equipment, storage handling systems;

- 5) Rotary shafts, press rolls, blades, impellers, etc. in high-strength, corrosion-resistant environments;

- 6) Cargo boxes for ships or trucks;

- 7) Food processing equipment;

- 8) Others.

Tags

Grade 2205, Type 2205, Inox 2205, AISI 318LN, SUS 329J3L, 1.4462, UNS S32205, UNS S31803, Acero 2205.

Contact

If you want to buy S32205 stainless steel products, please contact the RIGHT supplier - CIVMATS to get the latest price.

Chemical Composition

Data Sheet

| ASTM / AISI | DIN | JIS | GB |

|---|---|---|---|

| S32205(S31803) | 1.4462 | SUS329J3L | 022Cr22Ni5Mo3N |

| Heat Treatment Temperature |

σb (Mpa) | σs (Mpa) | δ% | HB | HRB | HV |

|---|---|---|---|---|---|---|

| °C | ≥ | ≥ | ≥ | ≤ | ≤ | ≤ |

| 1050-1100 | 655 | 450 | 25 | 293 | 31 | / |