Equipment Corrosion During Urea Production

In industrial production, urea is synthesized by liquid ammonia and carbon dioxide, following the below reaction formula under a pressure level of 14-25MPa and temperature of 180~210℃.

Pre-reaction raw materials like carbon dioxide and ammonia have weak corrosion, so do post-reaction products urea and water. However, reaction intermediate products like ammonium carbamates can exert strong corrosive effects under high temperatures. Meanwhile, urea produced during synthesis reaction can generate cyanic acid and ammonium cyanate. In water, CNO- ionized from cyanic acid and ammonium cyanate have strong reducibility like chloride ions, damaging the oxidation film on the stainless steel surface. Due to the strong depassivation effect, even stainless steel containing Molybdenum can hardly resist its corrosion. Hence, it is not until the addition of corrosion inhibitor to the corrosive medium does stainless steel have wide application in urea production.

Stainless Steel Application in Urea Production

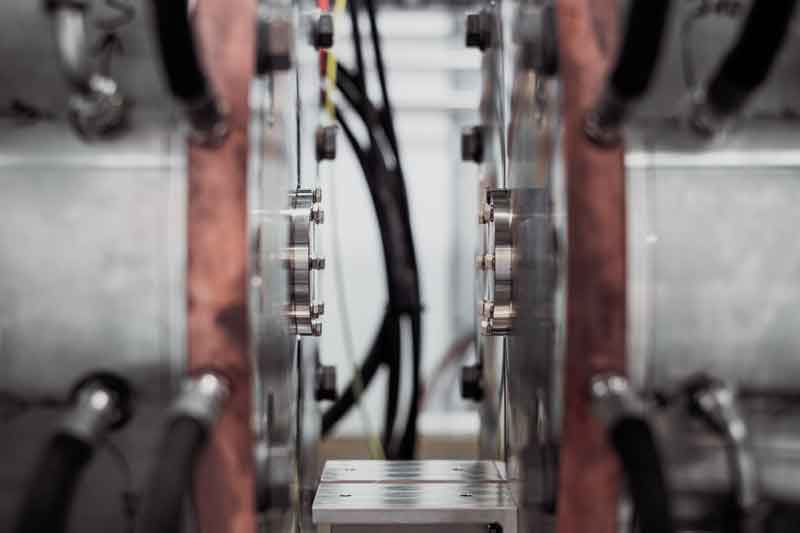

Stainless steel is generally selected as the material to make ammonia production equipment, ammonium nitrate production equipment, and urea production equipment. In some manufacturers’ practical applications, different parts are using distinct stainless steel materials to achieve cost efficiency.

Austenitic stainless steel 06Cr19Ni10 (304) is applied in the inside of ammonia converter, nitric acid preheater, low-pressure neutralizing tower, and inspissator. Austenitic stainless steel 022Cr17Ni12Mo2 (316L) is used for synthetic tower, high-pressure condenser and syringe. Austenitic stainless steel 022Cr25Ni22Mo2N(310MoLN) is chosen for the distributing pipes of stripping tower. 06Cr19Ni10(304) or 022Cr17Ni12Mo2(316L) is employed in prilling tower. 022Cr25Ni7Mo4N(2507) is harnessed in the body of ammonium carbamate pumps. Duplex stainless steel 03Cr25Ni6Mo3Cu2N(255) is used in valves; Austenite 12Cr18Mn9Ni5N(202) or 12Cr18Mn10Ni5Mo3N is leveraged for inner parts of urea synthesis tower, evaporator, nitric acid underground storage tank and ammonium nitride vacuum evaporator. Stainless steel 022Cr14Ni14Si4 is used to make concentrated nitric acid equipment such as evaporator and storage tanks. 022Cr17Ni5Si4N is used for manufacturing fuming nitric acid absorption tower, tankers, etc.