What is chemical corrosion?

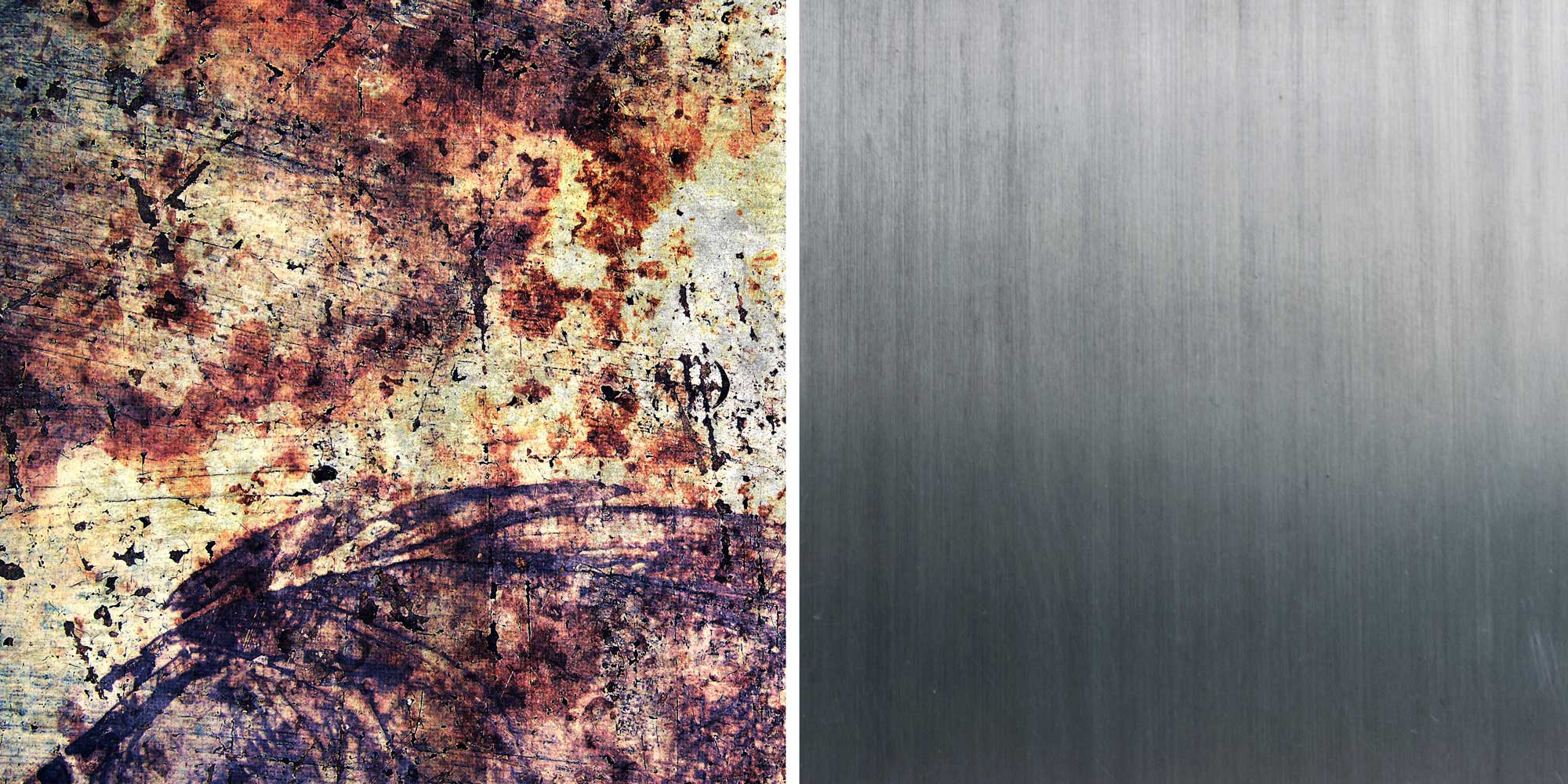

When metal is exposed to and reacts with the dry gas and nonelectrolyte solution, it will produce corrosion. The corrosion is known as chemical corrosion. The chemical corrosion product exists on the metal surface, without any current being generated during the corrosion process.

If the compounds produced by the chemical corrosion are stable, not easy to evaporate and dissolve, of dense tissue and binding strongly with metal matrix, the corrosion products will stay attached to the metal surface to form a passivation layer, hence to protect the metal matrix from further corrosion. This behavior is known as "passivation effect."

On the contrary, if the compounds are unstable, volatile or dissolved, not bonding with the metal strongly, the corrosion products will be peeling off layer by layer, like the oxide, hence unable to protect the metal matrix from further corrosion. this behavior is known as "activation."

Why Stainless Steel is Corrosion Resistance?

Ordinary carbon steel reacts with oxygen of the atmosphere to form an oxide film on the metal surface and keeps oxidizing, which results in expanded rust, forming a "thousand-layer Cake" type of corrosion until the rotten wear.

Stainless steel, in contrast is corrosion resistant. The “stainless” property is related to the chromium contained within the steel. As the chromium contained reaches 12%, the stainless steel reacted with the atmosphere will produce a passivation film (Cr2O3) on the surface, a dense chromium-rich oxide that effectively protects the stainless steel surface from further oxidation. This oxide film is so thin as to only a few microns; through the chrome the natural luster of the surface can be seen, hence the stainless steel has a unique surface. Moreover, if the surface is damaged, the exposed steel will react with the atmosphere to self-repair and regenerate the oxide, the "passivation film," for resumed protection. Hence, there is one thing in common all stainless steels share, that is, at least 10.5% chromium.

If the passivation film on the surface is damaged, the chromium in the steel will react with the oxygen in the atmosphere to produce new passivation film for continuous protection. Stainless steel, when exposed to special environments, will also incur some local corrosion, such as pitting, intergranular corrosion, stress corrosion, galvanic corrosion and so on.

In order to avoid the local corrosions, molybdenum, nitrogen, titanium or niobium will be added to the steel. Meanwhile, the new varieties such as low-carbon stainless steel, ultra-low carbon stainless steel, and duplex stainless steel are developed to enhance the corrosion resistance. All these metals react with oxygen in the atmosphere and form an oxide film on the surface. Unfortunately, the iron oxides formed on ordinary carbon steel keeps oxidizing, causing expanded corrosion and eventually holes. Although paints or oxidation-resistant metals e.g., zinc, nickel and chromium can be employed for galvanization to ensure the carbon steel surface, this protection is only a film. If the protective layer is damaged, the steel below will start to rust.

The corrosion resistance performance of stainless steel depends on chromium. However, since chromium is just one of the components in the steel, the method of protection varies. As the chromium added amounts to 10.5%, the steel resistance to atmospheric corrosion increases significantly. When more chromium is added, the corrosion resistance will be enhanced further, but not obvious. The reason is that chromium alloying changes the type of surface oxide into another type of surface oxide similar to that formed on pure chromium metal. This chromium-rich oxide tightly adhered protects the surface against further oxidation.

Contact

CIVMATS produces stainless steel products, such as pipes & fittings, bars. If you are in demand, please contact us:

- Company: CIVMATS CO., LIMITED

- Phone: 86-519-81809659

- Fax: 86-519-81809959

- Email: sales@civmats.com

- Address: 10th Floor, Xin Cheng Nan Du, Wujin District, Jiangsu, China

- Website: www.civmats.com